Garrison Steel is a premier Structural Steel Fabricator and Erector. Garrison fabricates and erects large structural steel projects such as stadiums and schools.

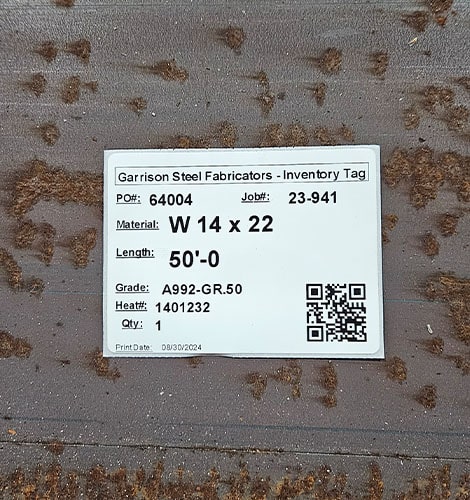

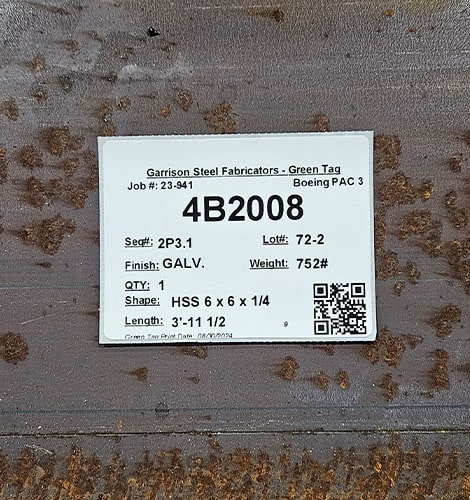

As part of their steel production and erection process, Garrison creates labels with the job and assembly number to apply to beams and other parts. These labels enable field teams to quickly identify pieces at the job site. They also label steel inventory with P.O./Job & Heat Numbers for use on fabrication projects.

The Problem

Previously, Garrison was using a 3rd party application to generate the labels. This required production staff to:

- 1

Acquire the job KISS file (a standard file used in steel detailing that describes the assemblies)

- 2

Import the KISS file into the 3rd party application to update its own database

- 3

Filter through the 3rd party application fields, which could take a considerable amount of time

- 4

Find and print the necessary labels from the 3rd party application

- 5

Also, if any information was changed or updated in Tekla Power Fab it would then void the information printed on the sticker, which meant repeating steps 1 through 4 above.

Altogether, this was a time-consuming process that also created duplication and opportunities for problems on the production floor.

The Solution

Garrison partnered with LTC Software Solutions to create two custom label reports right within Tekla PowerFab, the primary production planning and tracking tool used at Garrison Steel. One for production tracking, and one for inventory labeling.

LTC created reports that works seamlessly from within the production workflow and prints to specialized 4” x 3” zebra printers to create the label stickers with just a few clicks. Additionally, Garrison can now edit the report themselves, enabling them to further refine their process easily in the future. This allows Tekla Power Fab to remain the sole database for their production workflow. No more importing and updating a separate database.

Business Impact

With this solution in place: